5-Axis Non-Planar 3D Printer

Organization: Carnegie Mellon University, Pittsburgh USA

Timeline: Sep 2025 – Dec 2025

Multi-DOF Systems · Kinematics · Calibration · Mechatronics · Motion Coordination

Problem Context

Conventional FDM 3D printers are limited to planar layer deposition, leading to weak inter-layer bonding, increased support material, and constrained surface quality on curved geometries. Enabling non-planar printing requires coordinated multi-axis motion, accurate kinematic modeling, and reliable calibration across additional rotational degrees of freedom.

This project focused on designing and validating a custom 5-axis FDM printer capable of stable, coordinated motion for non-planar printing within the constraints of a modified Cartesian platform.

System Overview

The system extends a standard Cartesian FDM printer by integrating two additional rotational axes, enabling dynamic nozzle orientation during printing. The printer executes coordinated motion across five degrees of freedom to maintain nozzle alignment with curved surfaces while preserving print stability.

Mechanical design, kinematic coordination and calibration workflows were integrated into a single system and validated through live non-planar printing demonstrations.

My Role & Responsibilities

Role: Mechatronics design lead

Owned the RotB subsystem and led the integration of both rotational axes into a cartesian printer to

enable 5-axis motion for non-planar printing.Ensured electrical wiring stability across continuous bed rotation, addressing cable routing to prevent

signal interruption during multi-axis motion.Developed calibration procedures to align the rotational axes with the Cartesian coordinate frame,

including rotational zeroing, nozzle homing consistency, and bed-level alignment.

Key Technical Decisions

Selected a moving Z-bed with XY nozzle architecture instead of an XY bed and Z nozzle configuration to simplify kinematic modeling and coordinate transformations for multi-axis motion.

Chose a hybrid Cartesian + rotational axis design to balance mechanical complexity with controllable kinematic behavior for non-planar printing.

Used the Octopus Pro mainboard to support synchronized control of multiple stepper motors and enable future expandability for additional axes and sensors.

Prioritized mechanical calibration and repeatability over aggressive motion speeds to ensure stable coordinated printing across all five axes.

Results & Impact

Successfully demonstrated stable, coordinated five-axis motion for non-planar printing on a modified FDM platform.

Validated system performance through live non-planar printing demonstrations at the CMU MechE Exhibition.

Earned Best Overall Project and Best Innovative Project awards, recognizing system-level design, execution, and innovation.

Learnings & Limitations

Backlash introduced by 3D-printed gears significantly affected rotational axis precision, highlighting the importance of material choice and gear quality in multi-axis systems.

PLA gear deformation and belt tension loss under prolonged operation impacted repeatability, especially during long print cycles involving sustained motion.

Reliance on customized open-source slicers limited optimization for non-planar toolpaths and constrained achievable performance.

Future iterations would benefit from improved transmission mechanisms, thermal-stable materials, and tighter integration between slicer-level planning and machine kinematics.

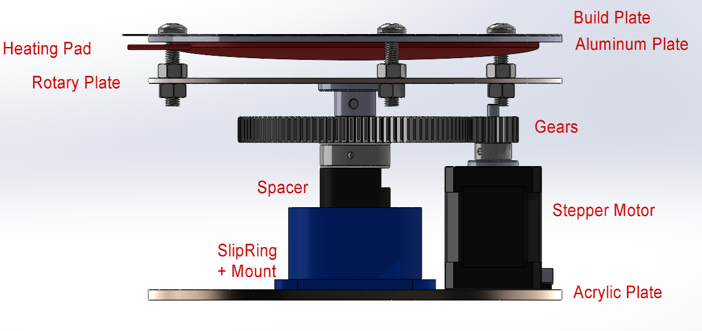

Full CAD View of the 5-Axis 3D Printer

A Axis Subassembly: Provides up to 90° bed tilt using a belt–pulley mechanism with integrated limit switch for homing.

B Axis Subassembly: The B Axis enables 360° rotation with 5:1 gear ratio and slip-ring integration for continuous bed motion.

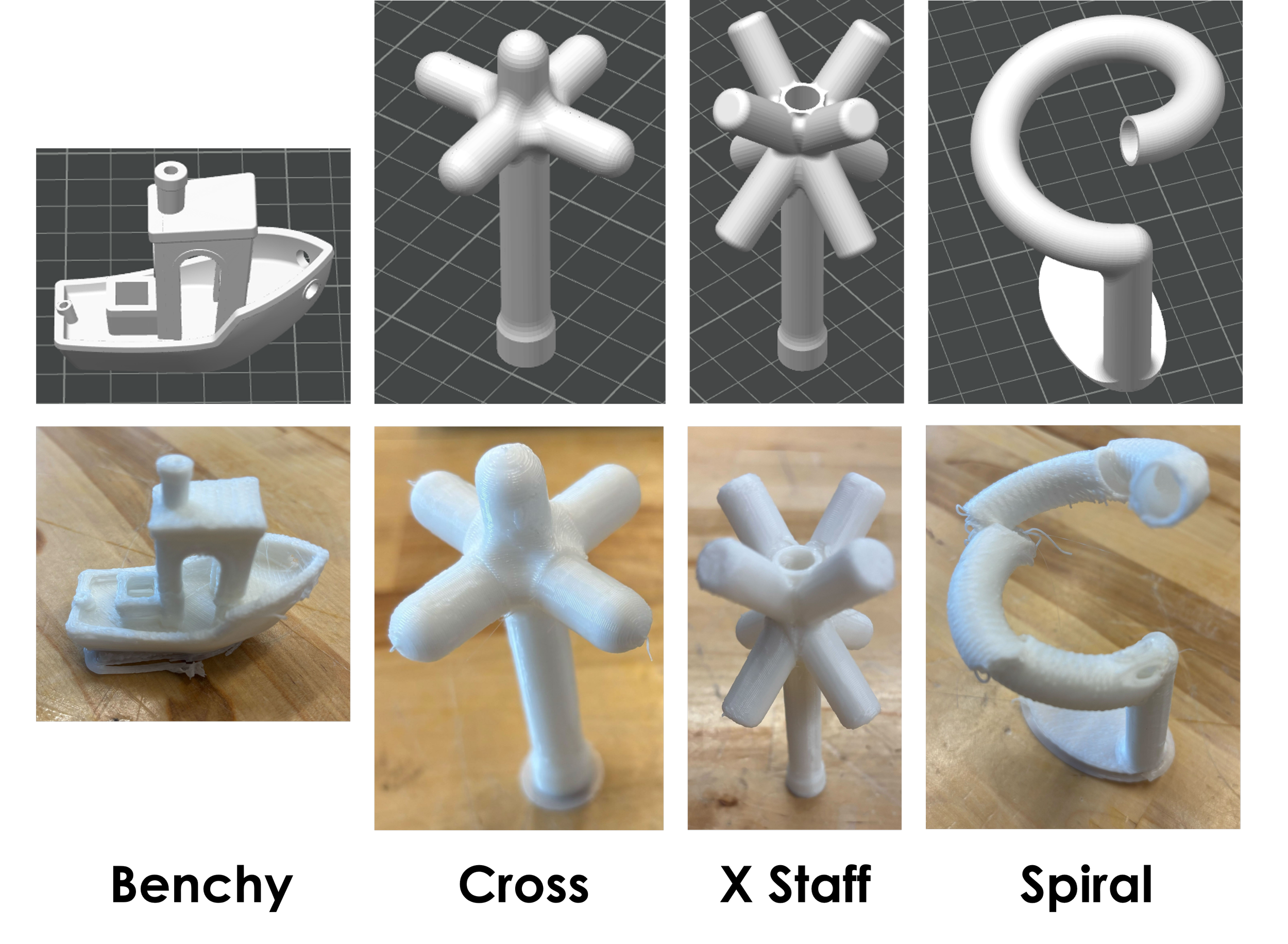

Test Prints: Slicer vs actual printed parts

Project Demonstration