Automatic Earthquake Refuge Bed

Organization: SRM Institute of Science & Technology, India

Timeline: Jan 2024 – Jun 2024

Mechatronic System Design · Seismic Sensing · Embedded Systems · Mechanical Design · IIoT · Patent

Problem Context

During high-magnitude seismic events, occupants often have only a few seconds (or no meaningful opportunity at all) to react before structural failure or falling debris occurs. In such scenarios, reliance on manual protective actions becomes unreliable, significantly increasing the risk of injury or entrapment when individuals are unable to reach safe shelter in time.

This project focused on developing an automated refuge bed capable of detecting verified seismic activity and rapidly deploying a protective structure without human intervention, providing immediate shelter and post-event survivability within residential environments.

System Overview

The system combines a foldable mechanical refuge structure with multi-sensor seismic detection and emergency communication. Vibration and accelerometer data are continuously monitored to detect seismic events, triggering automatic mechanical deployment only after verified thresholds are met.

Once activated, the system deploys a protective enclosure, initiates emergency alert transmission via GPS-enabled communication, and provides essential survival support until rescue.

My Role & Responsibilities

Role: System design and Integration lead

Conceptualized and led the end-to-end product design from initial concept through functional prototype.

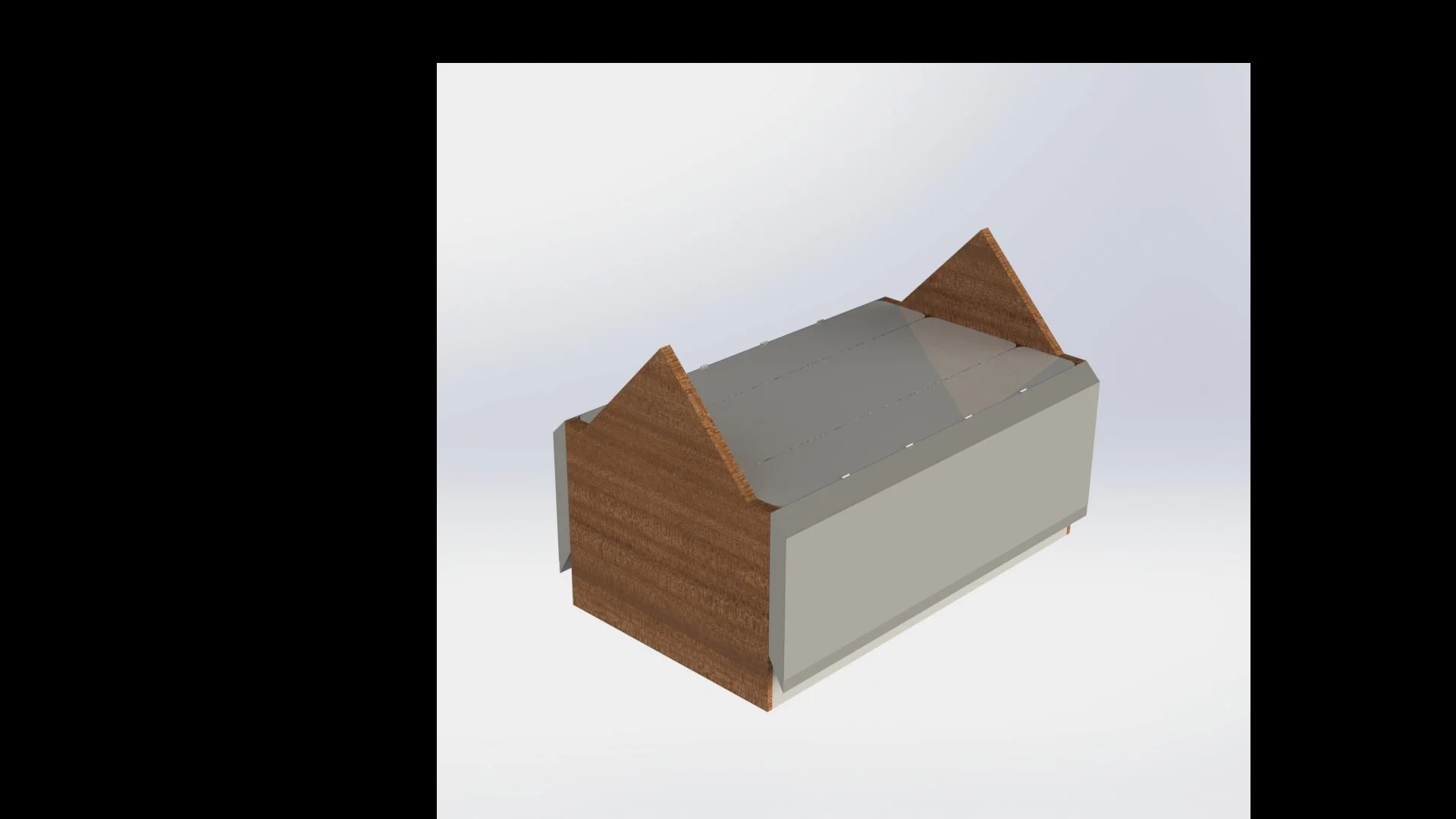

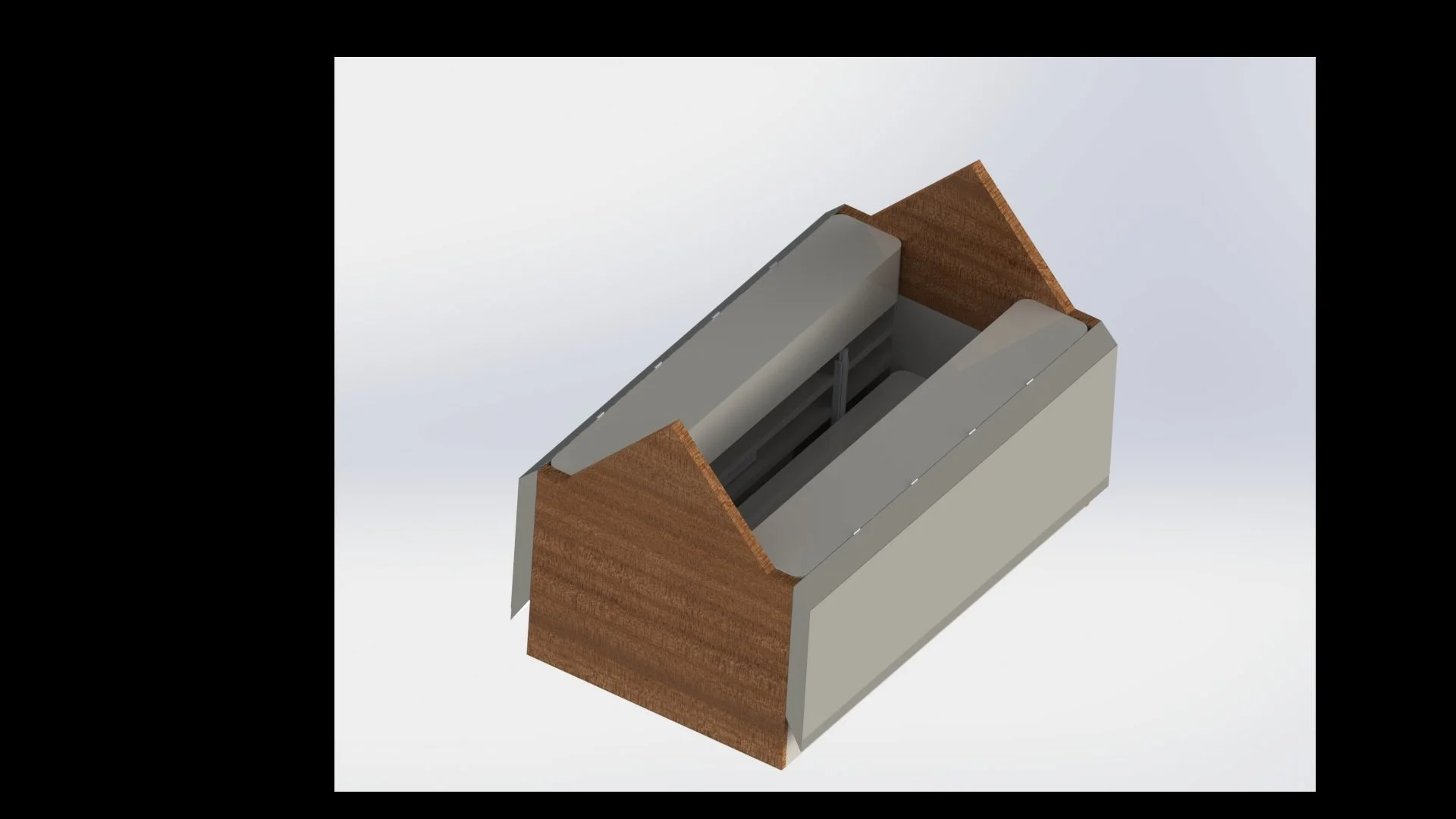

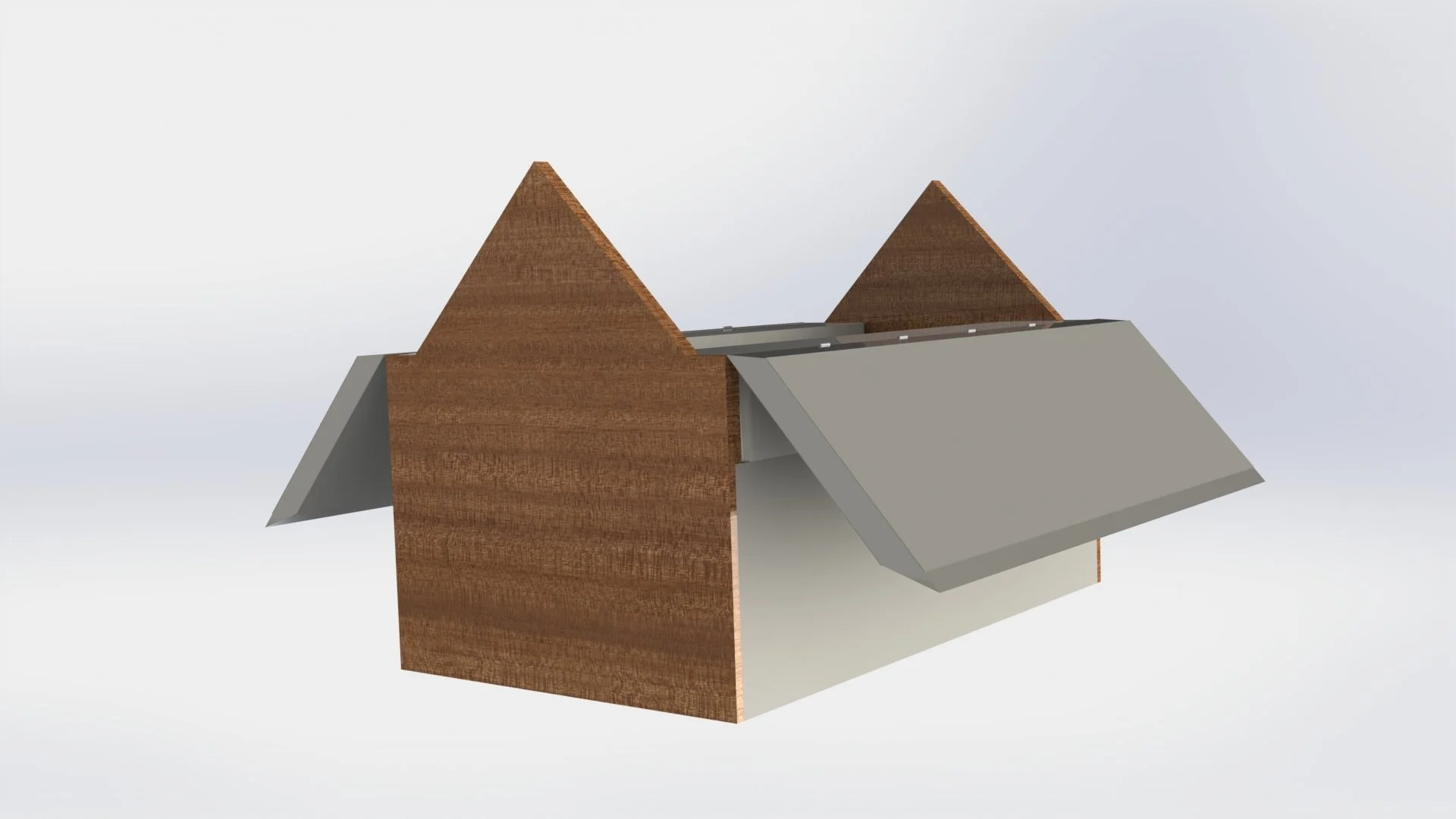

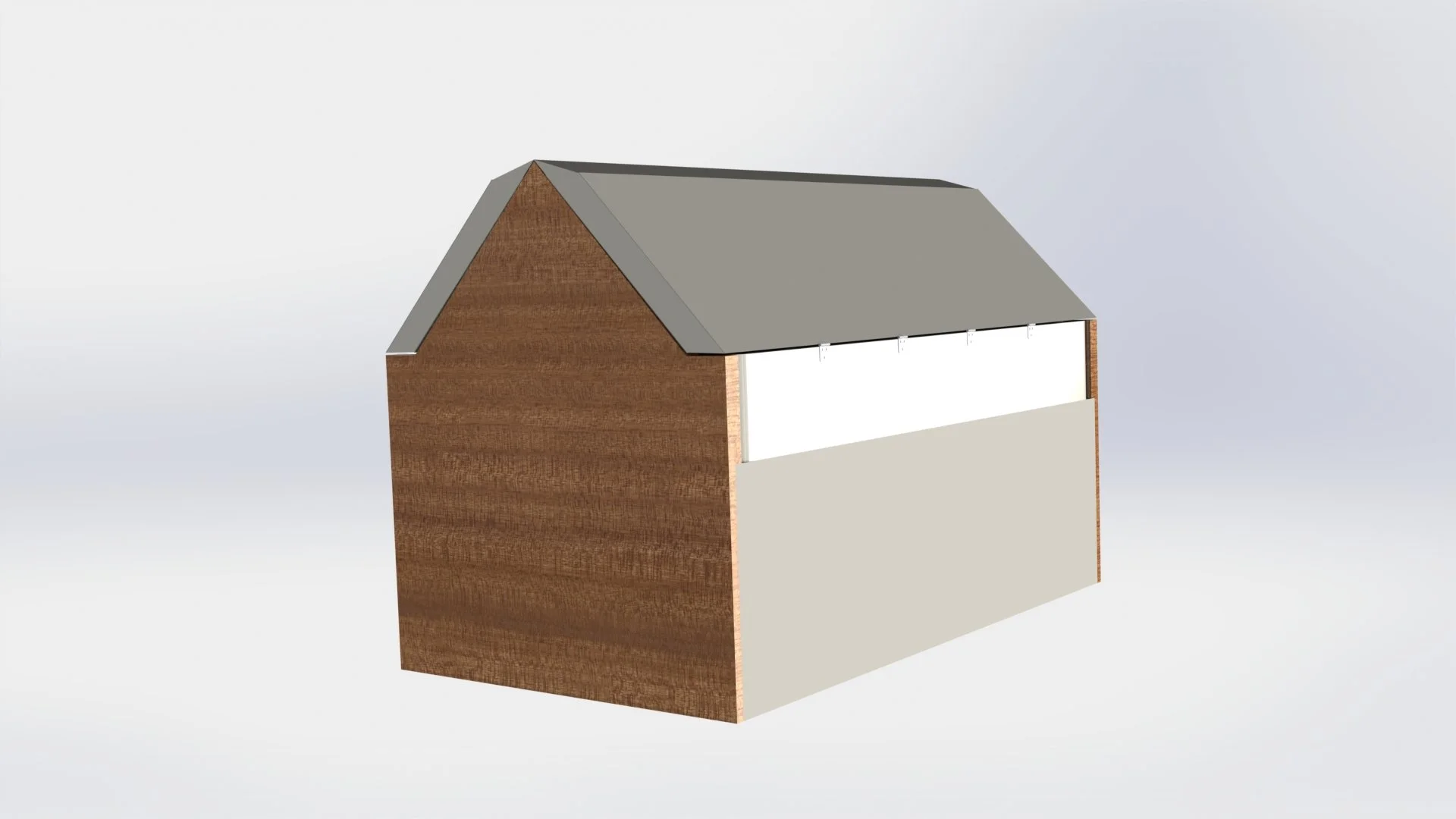

Designed the foldable mechanical refuge structure in SolidWorks, integrating actuators, sensor mounts, and safety mechanisms.

Developed a multi-stage seismic verification algorithm using vibration and accelerometer inputs to reduce false activations.

Integrated GPS-based communication modules to automatically transmit distress alerts and location data after deployment.

Designed oxygen and supply compartments and implemented manual override mechanisms to ensure occupant safety.

Key Technical Decisions

Used a multi-sensor, multi-stage verification approach to differentiate seismic events from environmental

vibrations and avoid accidental deployment.Prioritized mechanical reliability and fail-safe behavior over speed alone in the deployment mechanism.

Designed the structure to remain functional under partial collapse and debris loading scenarios.

Included manual override and passive safety features to ensure usability even in power-loss conditions.

Results & Impact

Achieved automatic deployment within 3.2 seconds of confirmed seismic trigger.

Demonstrated reliable activation only under verified seismic conditions during testing.

Filed an Indian patent for the system architecture and deployment mechanism (2024).

Proposed as a low-cost, residential-scale disaster-response solution for earthquake-prone regions.

Learnings & Limitations

Designing safety-critical systems requires conservative thresholds and verification logic to balance responsiveness with false-trigger prevention.

Mechanical deployment reliability is highly sensitive to packaging, actuator selection, and tolerance stack-up.

Future iterations could incorporate structural health monitoring and battery redundancy to improve resilience during prolonged events.

Multi-Stage Verification Process Flow

Normal Bed Design (with Mattress)

Earthquake Refuge Bed Design (with inside compartments)

Folding mechanism - sheds folds from sides to create a shelter

Closed shelter Bed during severe seismic events